6.3 Open Lid Assembly. Must make sure that the interior pressure is zero before SLOWLY loosening up the Locking Ring Handle and opening up the Lid Assembly;

6.4 Remove Used Filter. It is important to dispose used filters according to local environmental regulations;

6.5 Basket Inspection. Inspect for any basket damages. Warning: Operating without Basket or with damaged Basket will cause major filter failures. Basket is a component that supports the bag filter under pressure. A bag filter is NOT designed to resist pressure by itself;

6.6 Install New Filter. For PP-HOUSING, filter bags must be completely inserted into the Basket, until it touches the bottom of the Basket; For HPPCARTRIDGE HOUSING, the SOE end cap of cartridge must be insert completely into the Cartridge Seating Plate to seal;

6.7 Gasket Inspection. Choose chemically compatible Gasket for specified operation. Replace worn Gasket immediately with genuine SCC gaskets;

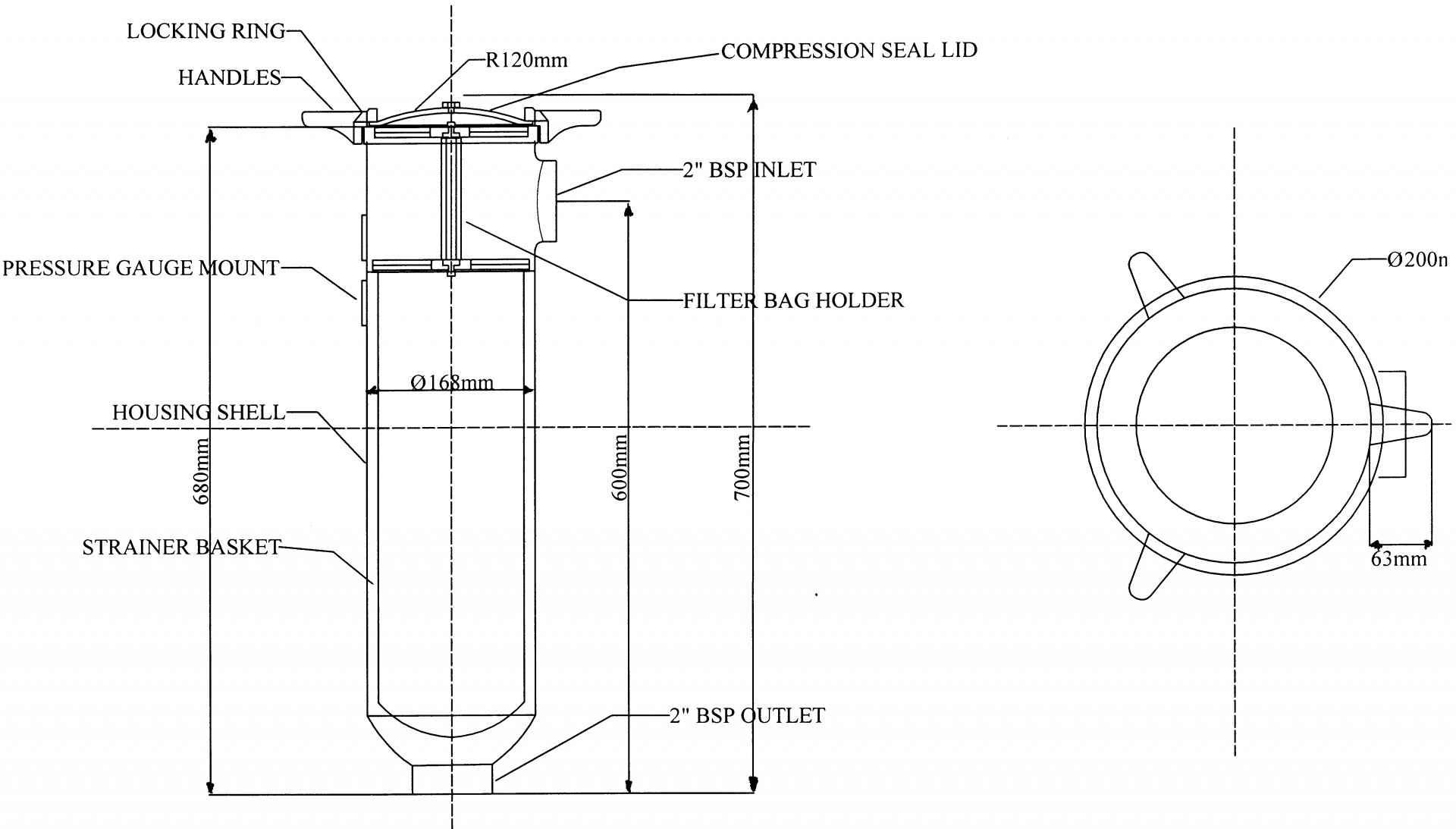

6.8 Reinstall Lid Assembly. Pay special attention when reinstall the Lid Assembly. Steadily place the dome-shapped Compression Seal Lid Assembly on top of the housing shell. Cross fist-tap the Locking Ring Handle to line up the Locking Ring Handle’s female threads with housing shell’s male threads correctly, then SLOWLY tighten the Locking Ring Handle. Under any circumstances, DO NOT tighten the Locking Ring Handle by excessive force, before the threads are correctly lined up, or over-tighten the Locking Ring Handle, as it may cause seal and mechanical failures, and may resulte in serious jobsite injuries;

6.9 Open Inlet Valve. SLOWLY Open the Inlet Valve while keepING the Vent Valve open to bleed trapped air out. Then turn Pump back on;

6.10 Close Vent Valve. Cover the Vent Valve Nozzle with a cup to avoid spoilage. When the first drip of liquid is observed from the Vent Valve Nozzel, close the Vent Valve. At this point, the housing is fully bled;

6.11 SLOWLY Open Outlet Valve. Observe for leaks. Shall leakage takes place, shut off Inlet Valve and Pump, start over again from Item 6.8.

7. Need to Knows

7.1 Differential Pressure: It is important to check pressure differential regularly during operation. Operating above the recommended 1.10 kg/cm² filter replacement pressure differential will negatively affect flow rate, reduce production efficiency.

7.2 System Failure: If pressure differential suddenly drops, stop operation immediately and check for possible seal failure and/or filter rupture.

7.3 Bypass: Filtration brings about pressure differential. Pressure differential will gradually build up as filters retain more and more contaminants. No pressure differential and/or no pressure differential increase means no actual filtration is taking place. Stop operation and check for possible seal failure and/or filter rupture.